Tipping drums is an essential part of many industrial processes. Our drum rotators provide a safe way to lift and tip various drum types and sizes, and we can customise each rotator to suit your exact needs.

ATEX Drum Dumper

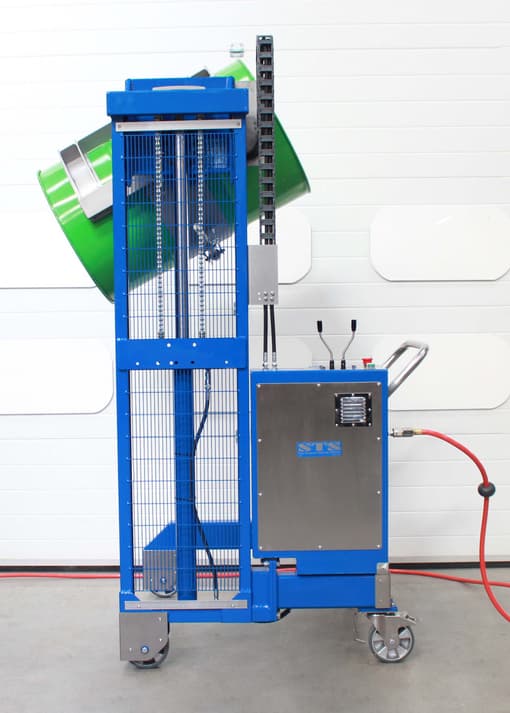

Custom-built ATEX pneumatic-hydraulic drum dumper for 205-litre steel and plastic drums and certified for use in Zoned areas.

Customer requirements

- ATEX certified, Zone 1 unit required

- Side tipping is required to keep the unit short in length

- Air/pneumatic-powered system

- Must handle steel and plastic 205-litre drums

- Load capacity of 350kg

Our customer had a small space envelope to work within. They needed to lift and tip drums at a low level and required no forward tipping reach. A side-tipping drum dumper was the best solution as the unit was compact (front to back). We issued 3D CAD drawings of the proposed unit to the customer for review before manufacture.

The control panel was located on the side of the unit. It featured two levers for the lift and rotation controls. As the unit was air-powered there was an 'operate' button that needed to be pressed before either lever would activate. The unit included all mandatory safety features such as an emergency stop button.

This drum dumper is another example of STS designing custom drum handling equipment to suit a specific need or requirement. If you have a project that requires drums or barrels to be handled get in touch to see how we can help. We are able to provide CAD drawings to demonstrate how our units would fit with the existing infrastructure.

Drum Rotators / Tippers

Contact Us

If you need a custom manual handling solution, we can design and manufacture the right piece of equipment to meet your specific requirements. Talk to us to find out how we can help you.