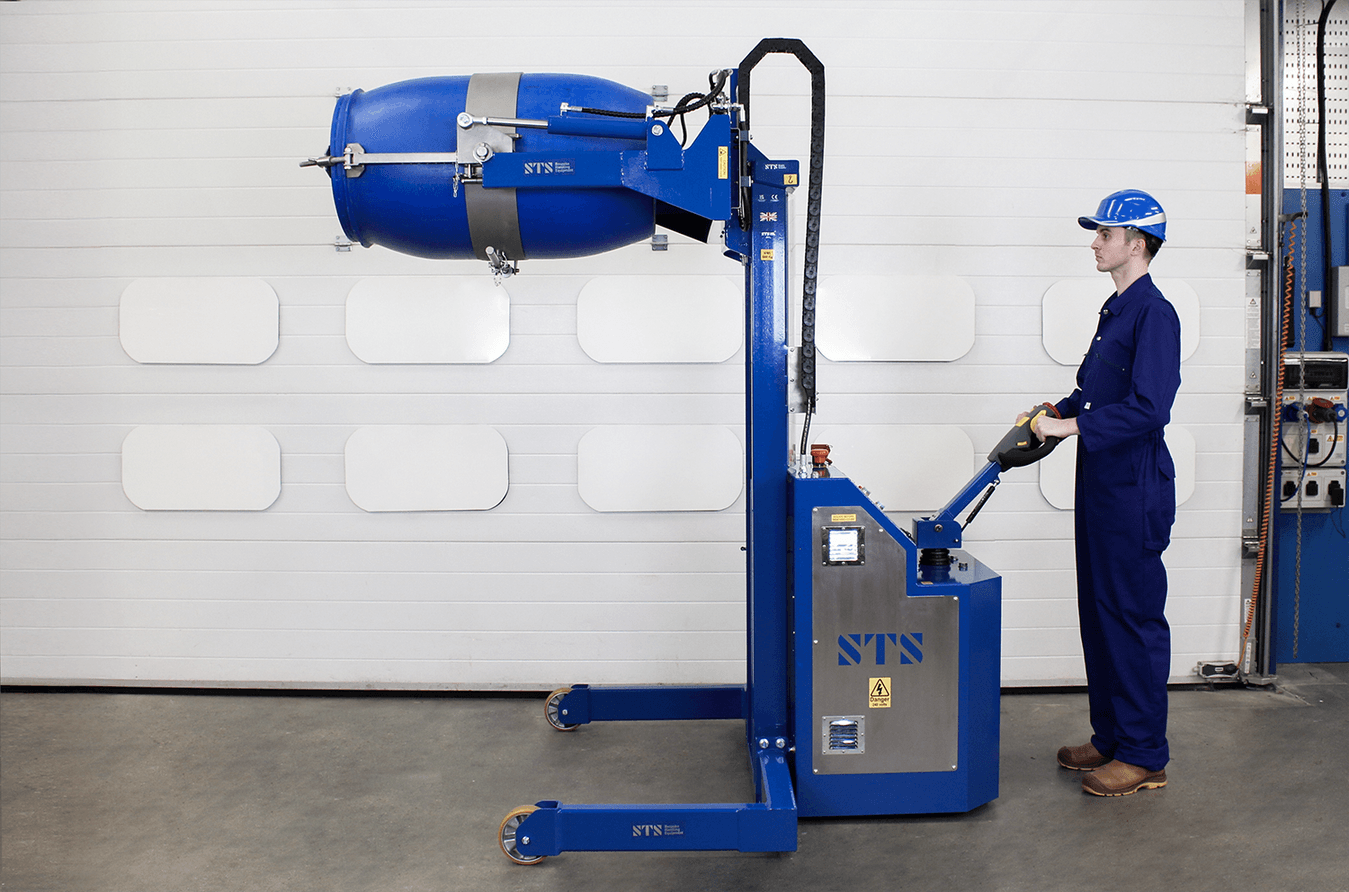

Tipping drums is an essential part of many industrial processes. Our drum rotators provide a safe way to lift and tip various drum types and sizes, and we can customise each rotator to suit your exact needs.

Heavy-Duty Drum Tipper for 500kg Drums

Tailor-made drum tipper improves operator safety and efficiency at South African sampling facility.

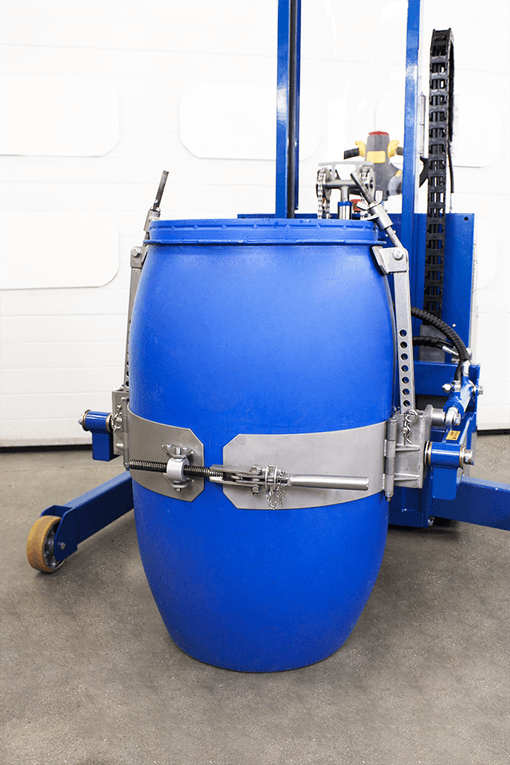

A South African client recently approached STS with a unique and challenging brief: design a robust, heavy-duty drum handling system to manage the safe decanting of 205-litre (55 US gal) MAUSER drums filled with up to 500kg (1,100lb) of rock samples.

Operators at the facility had been manually reaching into the drums and tipping them onto the floor once partially emptied to access the contents - individual bags of rock samples. This posed serious ergonomic and safety issues, particularly given the weight and offset load dynamics involved.

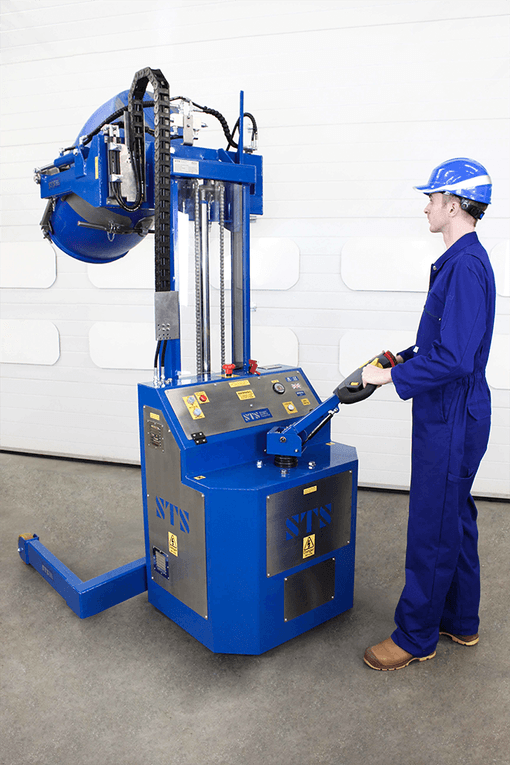

STS responded by engineering a bespoke drum tipper that combines strength, control, and safety. Unlike traditional gearbox-driven rotators, this unit utilises powerful hydraulic tipping rams to handle the extreme torque required when drums are half full and their centre of mass is off-centre. The lift height allowed the operators to improve their process. Instead of tipping the bags onto the floor, operators could raise the drums to waist height and decant them onto a table at an ergonomic working level.

The hydraulic system ensures smooth, controlled tipping, giving operators full command over the decanting process and eliminating the risks associated with manual handling. The unit’s design is tailored for rugged use, built to endure demanding conditions while maintaining precision and operator safety.

This project highlights STS’s capability to deliver specialist drum handling equipment that solves real-world problems, proving especially valuable in environments where off-the-shelf solutions fall short.

Drum Rotators / Tippers

Contact Us

If you need a custom manual handling solution, we can design and manufacture the right piece of equipment to meet your specific requirements. Talk to us to find out how we can help you.