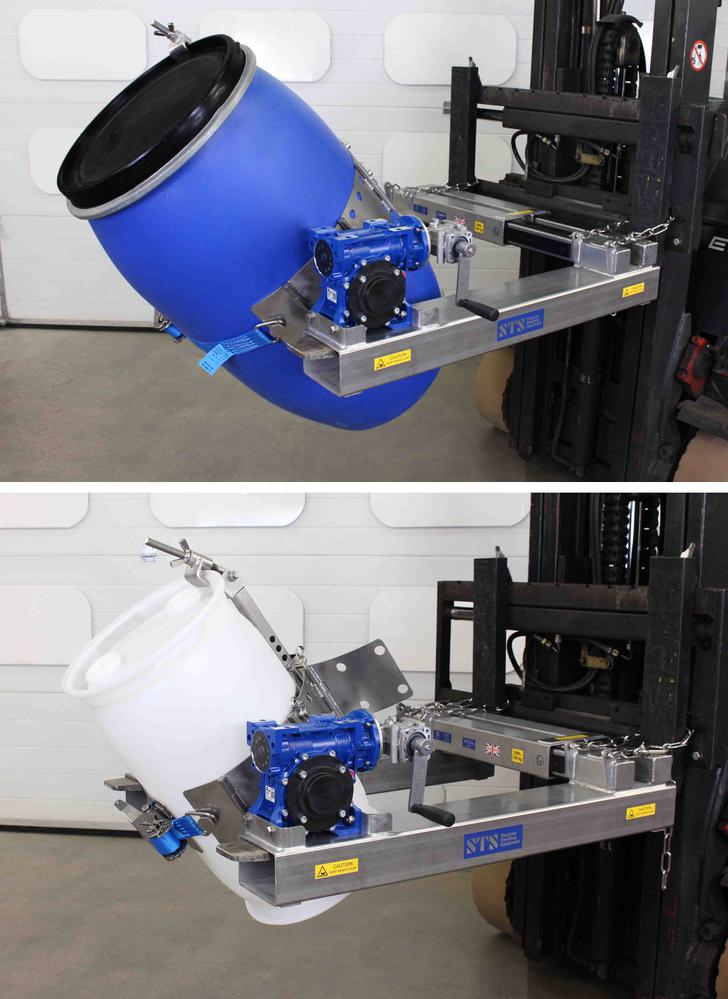

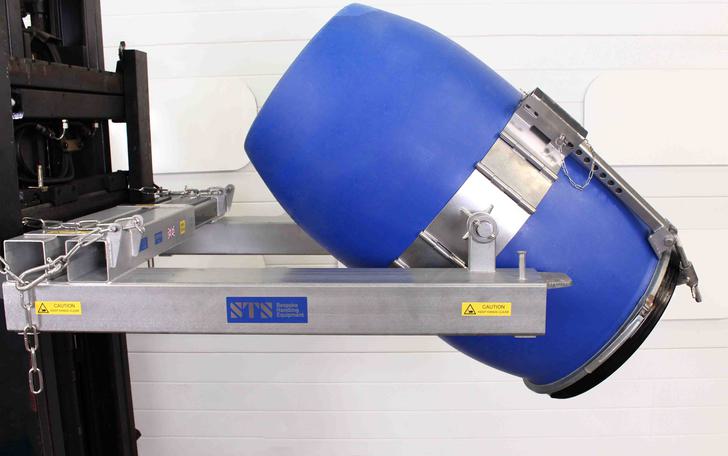

The unit is fitted with a stainless-steel fully-adjustable drum band that can handle steel, plastic, or fibre drums from 50- to 220-litres. Simply adjust the variable band to the size of the drum and secure the drum with the ratchet and polyester strap. We can also fit this unit with a fixed over-centre clamp band for companies only handling 200- to 220-litre drums. All of our drum rotator models include a high-quality self-locking rotational gearbox. This makes sure that when you’re rotating drums they always remain under control and never self-rotate.

Key product features

Universal drum band

Universal drum band

Sliding band mechanism

Sliding band mechanism

Unlike other units on the market that are fixed (and are therefore only suitable for 200-litre drums), our unit can be adjusted to accommodate drums from 50- to 220-litres with ease. The drum tipper frame itself utilises a sliding mechanism - as the forks are pushed closer together along the back frame, this allows the universal band to be adjusted to suit smaller diameter drums. Given suppliers regularly change drum sizes it is important to source a versatile drum tipper rather than one limited to just one drum size.

Fork pockets

Fork pockets

This unit is suitable for a wide range of forklift trucks. The unit is mounted onto the forklift using the two integral fork pockets. The frame is secured in place using large clamp nuts on both sides of the fork pockets.

This unit has a safe working load of 350kg and is supplied with a load test certificate. If you are handling drums in a confined area where forklifts pose a danger to personnel, we recommend one of our free-standing drum tippers - these models can be fitted with a wide range of powered features depending upon the amount of use.

Drum suitability

Drum suitability

Our ATEX / UKEX Forklift Drum Tipper Attachment is suitable for a wide range of drum types, sizes, and materials. For a detailed list of compatible drum types, see the drum suitability document below.

ATEX / UKEX-certified for gas and dust zones 1, 2, 21 and 22

ATEX / UKEX-certified for gas and dust zones 1, 2, 21 and 22

We can provide a fully-certified ATEX / UKEX Forklift Drum Tipper Attachment for use in hazardous zoned areas. Our DRU04-SS-Ex is constructed from 304-grade stainless steel, this eliminates any thermic-strike risk. This model is suitable for gas and dust areas: Zone 1, 2, 21, and 22. All our 'Ex' rated drum handling equipment is supplied with a manufacturer’s Declaration of Conformity which demonstrates compliance with the directives and relevant British and ISO Standards.

Specification

DRU04-SS-Ex Forklift Drum Tipper Attachment (ATEX)

-

Safe working load (SWL)

350kg

-

Drum compatibility

Steel and plastic drums, 50-220 litres (incl. MAUSER drums)

-

Band assembly

Segmented adjustable/universal band with 50mm stainless steel ratchet and polyester strap

-

Additional drum securing

Rim clamp included which grips the top edge of the drum preventing slippage

-

Rotation gearbox

Worm-wheel, self-locking with 120:1 ratio and manual handle

-

Construction

Stainless steel 304-grade construction

-

Metal preparation

Brushed finish with TIG brush chemically etched welds

-

Surface finish

Smooth clean stainless steel finish

-

Compatible with forklift truck

Yes

-

Compliance

EC Machinery Directive 2006/42/EC

ATEX Directive 2014/34/EU

Zones 1, 2, 21 and 22 CE Ex II 2 G D

Optional features

ATEX / UKEX option

We can offer an ATEX / UKEX version of this drum rotator model, suitable for use in zone 1, 2, 21 and 22 environments.Fixed-size drum band

If you’re only handling 200- to 220-litre steel and plastic drums, our fixed over-centre drum band makes securing and handling drums quicker.Sale or return

In the UK we can supply certain equipment on a sale-or-return basis, meaning you can use a unit on-site for seven days with no obligation to buy it once the trial period is up. Find out more here.

Technical specification

Instruction manual

Contact Us

Do you have a manual handling issue we could solve? We’d be happy to discuss any handling concerns and advise on the most suitable STS equipment. You can talk to us via telephone, email and social media.

Drum Rotators / Tippers

Tipping drums is an essential part of many industrial processes. Our drum rotators provide a safe way to lift and tip various drum types and sizes, and we can customise each rotator to suit your exact needs.