If you need a custom manual handling solution, we can design and manufacture the right piece of equipment to meet your specific requirements. Talk to us to find out how we can help you.

Custom Drum Handler for Olive Barrels

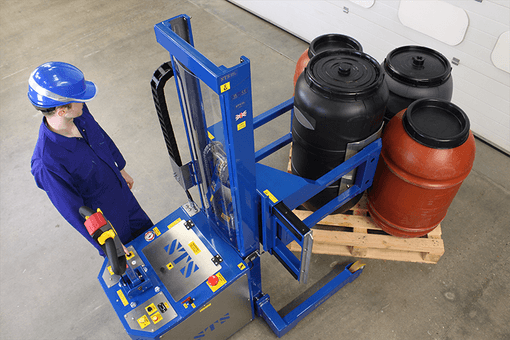

A bespoke drum handler designed to safely move slippery, tightly packed olive drums from pallets to conveyors.

Handling Slippery Olive Drums with Precision and Power

Two UK food manufacturers approached STS with a shared challenge: how to safely and efficiently handle 200-litre plastic drums of olives and pickles. These HDPE drums can be heavy and awkward, but also feature smooth surfaces that can be slippery and are delivered tightly packed, four to a pallet. Traditional drum handling equipment wasn’t up to the task.

STS responded with a custom-engineered solution. Designed specifically for handling these screw-top plastic drums, the drum handler combines powered clamping arms with a fully electric drive system to streamline and safeguard operations.

Tailored Features for Tight Spaces and Slippery Loads

The challenge lay in the unique design of the drums. To ensure a secure grip, STS developed bespoke clamping pads with proud metal lips that lift from beneath the rolling hoops around each drum’s midsection. The arms were designed to be slim enough to allow access between tightly packed drums on the pallet’s corners. This precise engineering eliminated the need for manual repositioning and significantly reduced handling time.

Powered Clamping and Efficient Movement

With hydraulically operated clamping pads and a smooth electric lift, operators can now approach a drum directly, clamp securely, and raise it with ease. The drive system, powered by onboard batteries, includes a rear-mounted tiller that controls progressive forward/reverse movement, ensuring safe and accurate drum placement.

Controls are intuitively located on the tiller and rear panel, giving operators full command over the machine’s lift, lower, clamp, and unclamp functions. Built-in safety features such as emergency stop buttons, a battery isolator switch, and an anti-trap tiller enhance operator protection.

Engineered for Reliability in Food Manufacturing

The custom drum handler was designed by our in-house design team, utilising decades of drum handling experience. Its ability to move slippery, heavy drums quickly and safely means it now plays a vital role in these customers' food-processing workflows.

This project highlights how STS applies thoughtful engineering and practical innovation to overcome complex manual handling challenges.