Our qualified engineers install the lift circuits and ensure they’re fully compliant. We fit mandatory safety features and emergency stops on all of our drum handling equipment to keep you and your operators safe.

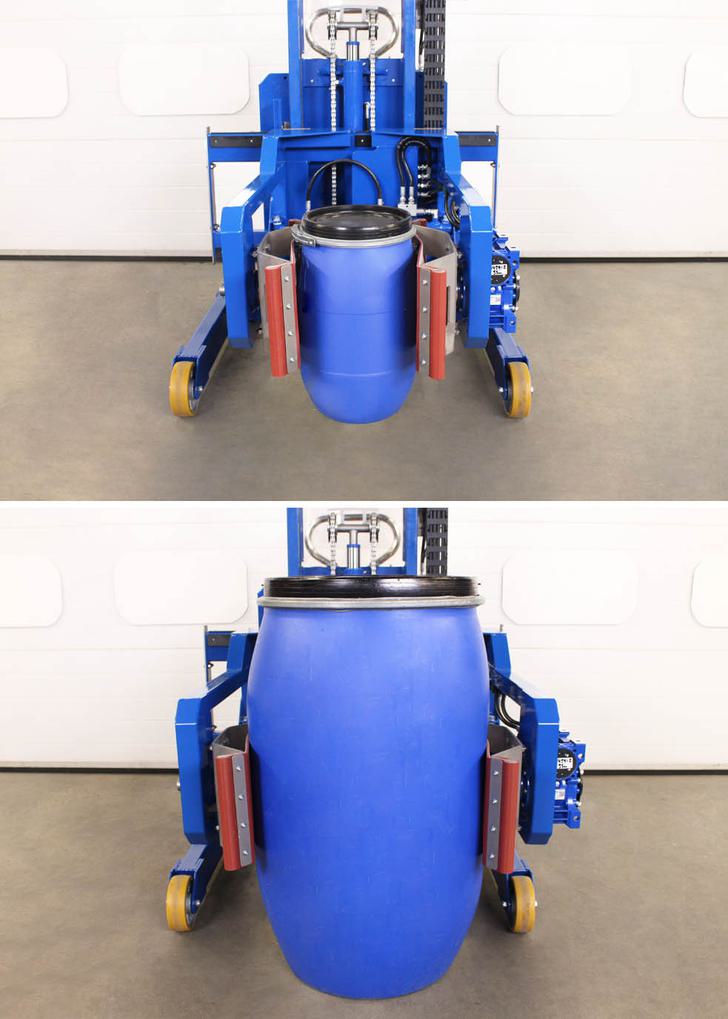

Each power-clamp drum rotator has a clamp pressure gauge located on the rear panel, operators are able to monitor the clamp pressure during use to ensure the drum remains clamped securely in the head. Burst valves protect hydraulic circuits from pressure drops should a hose be damaged during use.