All-electric lift drum tipper circuits we assemble are fully compliant with the relevant standards. Our engineers install mandatory safety features such as power isolators and emergency stop buttons to each and every unit. A battery condition meter located on the rear control panel informs operators of the state of charge of the battery; the unit makes use of a smart battery charger, this conditions the battery and when full provides a trickle charge.

Key product features

Fully compliant lift circuits

Fully compliant lift circuits

Universal drum band

Universal drum band

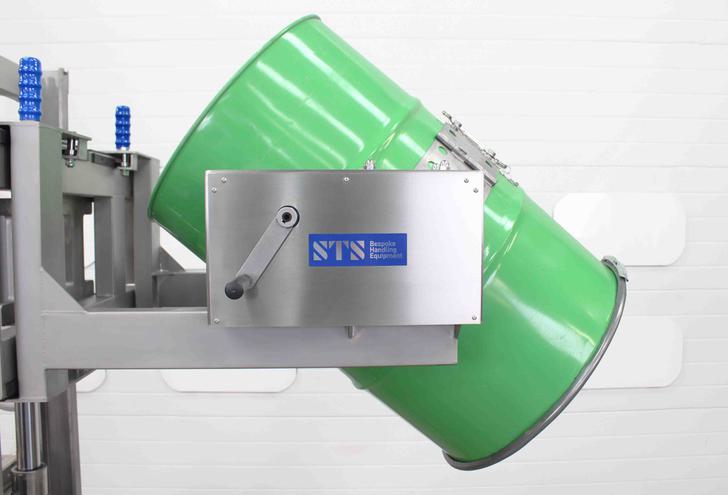

Drums are made using steel, plastic and fibreboard materials and sizes range from 50 to 220 litres. This model makes use of our universal drum rotator band. The segmented band can be adjusted to suit the range of drums mentioned above. Operators adjust the diameter of the band and then use the ratchet and strap to secure the drum in place. The band accommodates drums from 350mm to 600mm in diameter.

For applications where only 200- to 220-litre steel and plastic drums are being emptied, we can supply a fixed diameter over-centre drum band. This securing arrangement has a fixed diameter and used rubber pads to grip the drum. This band is very fast and simple to use making it a popular choice.

Stainless steel materials

Stainless steel materials

The chassis uses hot-rolled stainless steel channels which are strong and durable, stainless steel bearings run the lift carriage up and down the channels smoothly. The hydraulic lift ram and rotational gearbox assembly are both sheaved in stainless steel to protect them from corrosive environments. Stainless steel parts are either mechanically polished or aqua blasted using an aluminium oxide and glass bead blasting process. The finish of the stainless steel is both smooth and clean, well suited to food and pharmaceutical environments.

Self-locking gearbox

Self-locking gearbox

A self-locking rotational gearbox rotates the drum when an operator turns the handle; the self-locking properties of the worm-wheel gearbox means drums never self-rotates when the handle is let go of. The 120:1 gearbox ratio is easy to turn by hand and is therefore controllable by operators of all sizes and strengths. Where many drums are handled per day we can provide a power rotation model, the control to the rotation would be located on the rear panel in this case.

Controllable rear-wheel steering

Controllable rear-wheel steering

Steering is controlled using a tiller at the back of the unit. The steering moves both rear castors providing exceptional control and manoeuvrability. The unit can achieve a tight turning radius when being used in narrow work areas.

We use premium wheels and castors in the assembly of our equipment. All the wheels we use are fitted with precision ball bearings to minimise rolling resistance making the unit easy to move around the factory floor.

Drum rotator suitability

Drum rotator suitability

This INOX Universal Drum Rotator is able to handle steel, plastic and fibreboard drums of between 50- to 220-litres. View the drum suitability document below by clicking the button. If you are handling drums that are not shown and would like advice, please get in touch with our product team.

Specification

STE01-DRU01-SS Stainless Steel Drum Rotator (Electric)

-

Safe working load (SWL)

350kg

-

Functions

Powered lift/lower, manual rotation, manual push/pull

-

Power details

On-board 115Ah battery powering an electric-hydraulic pump, mains 230v, smart battery charger built into control box

-

Controls

Silicone booted buttons, emergency stop, removable key switch, digital battery condition meter

-

Lift height

1500mm

-

Tipping clearance

1400mm at 15° tip angle / 1325mm at 30° tip angle (205 litre drum)

-

Drum compatibility

Steel and plastic drums, 50-220 litres (incl. MAUSER drums)

-

Band assembly

Segmented adjustable/universal band with 50mm stainless steel ratchet and polyester strap

-

Additional drum securing

Rim clamp included which grips the top edge of the drum preventing slippage

-

Rotation gearbox

Worm-wheel, self-locking with 120:1 ratio and manual handle

-

Construction

Stainless steel 304-grade construction

-

Metal treatment

Aqua blasted and vibro-polished stainless steel parts, smooth clean finish

-

Guarding

Polycarbonate shatterproof clear guarding

-

Leg dimensions

Inside straddle width 850mm, total outside width 1080mm

-

Front wheels

Two fixed 160mm wheels, plastic centred with polyurethane tyres and precision bearings

-

Rear wheels

Two tiller steered 160mm wheels, plastic centred with polyurethane tyres and precision bearings

-

Noise

Less than 76 dBA

-

Compliance

CE / UKCA

Optional features

Powered drum clamp

Improve efficiency using hydraulic powered clamping arms. Our unique flexible pads can clamp drums from 50- to 220-litres.Powered drum rotation

For time-critical pouring applications we offer power rotation. You can control drum tipping from the rear panel of the machine.Power-drive system

When moving drums over long distances you may need power drive. Our electric power-drive tiller steering offers effortless control.Telescopic/variable lift height

Single- and dual-mast models are available, depending on the lift height required. Single masts offer around 1500mm lift whereas telescopic masts offer 2700mm.Variable leg dimensions

When machinery integration is critical, we can modify leg dimensions of the drum rotator to suit your facility.Fixed-size drum band

If you’re only handling 200- to 220-litre steel and plastic drums, our fixed over-centre drum band makes securing drums quicker.Load-cell weighing system

With our load-cell system you can weigh drums while you handle them. A digital read-out provides real-time weight information for quantity-sensitive processes.Very small drum insert

If you’re using drum handling equipment for drums smaller than 50 litres, we can provide an insert that allows you to lift small containers with the universal drum band.Sale or return

In the UK we can supply certain equipment on a sale-or-return basis, meaning you can use a unit on-site for seven days with no obligation to buy it once the trial period is up. Find out more here.

Technical specification

Instruction manual

Contact Us

Do you have a manual handling issue we could solve? We’d be happy to discuss any handling concerns and advise on the most suitable STS equipment. You can talk to us via telephone, email and social media.

Drum Rotators / Tippers

Tipping drums is an essential part of many industrial processes. Our drum rotators provide a safe way to lift and tip various drum types and sizes, and we can customise each rotator to suit your exact needs.