ATEX and UKEX classified areas require zoned equipment. We offer air-powered equipment for use in these zoned areas. An airline connection powers a pneumatic-hydraulic pump, which in turn supplies oil to the hydraulic lifting system. The pneumatic system is very robust and requires a minimal amount of maintenance even in high-duty environments. We are able to supply drum handling equipment with additional air-hydraulic functions including power clamp, rotation and drive - these options improve efficiency in the workplace by increasing the speed of operations.

Key product features

Air-powered functions

Air-powered functions

Universal drum band

Universal drum band

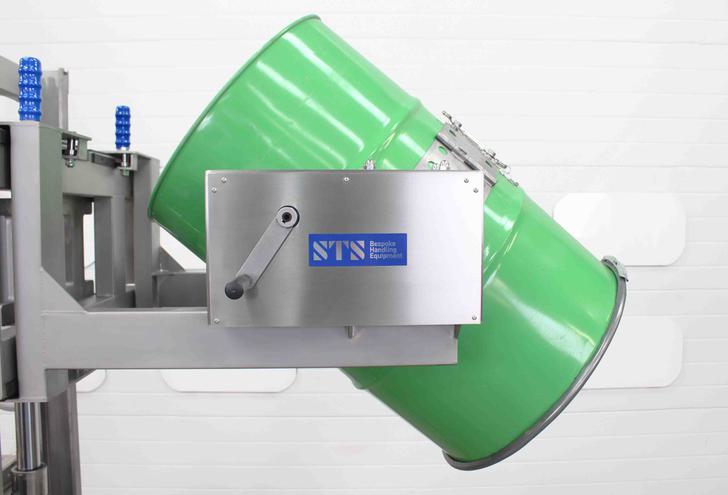

If your company handles a range of drum types and sizes the DRU01 universal band arrangement will allow you to handle them all with the same unit. The band assembly uses a modular design which is unique within the drum-handling space. Each section of the band adapts to the curvature of the drum to ensure they are always held securely.

Adjust the diameter of the band quickly and easily by removing two pins. Once set to the correct diameter, the pins can be put back in place. The band is designed to handle drums from 50 litres, right up to 220 litres. Drums that can be handled include steel, plastic and cardboard. If your company only uses 200-litre drums we can supply a fixed-diameter drum band (FB option) which uses an over-centre clamp, this band is suitable for 200- to 220-litre steel and plastic drums only.

Stainless steel materials

Stainless steel materials

We use German hot-rolled stainless steel channel profiles in the construction of our lifting chassis. The hot-rolled channels are very strong and provide a solid foundation for all our stainless steel drum tippers.

Stainless steel precision bearings allow the lift carriage to move up and down the chassis with a minimal amount of friction. The hydraulic lift ram and rotational worm-wheel gearbox are both protected within stainless steel to safeguard them from corrosion. All stainless steel parts used are either polished using mechanical equipment or aqua blasted using an aluminium oxide and glass bead blasting system. The finish of the stainless steel is smooth and clean making it an ideal choice for use in clean manufacturing areas including Good Manufacturing Practice (GMP) areas.

Self-locking gearbox

Self-locking gearbox

Models with manual rotation feature a self-locking worm wheel gearbox arrangement. The gearbox assembly is made up of a primary and secondary worm wheel gearbox along with a 90°bevel gearbox. The system has a ratio of 120:1, this makes the rotation handle easy to turn for operators of all strengths and also prevents any self-rotating of the drum when the handle is let go. During transport, the gearbox handle can be folded away to prevent damage. We also offer hydraulic powered drum rotation which is a great addition when tipping many drums each day - it can increase the speed and efficiency of operations.

Controllable rear-wheel steering

Controllable rear-wheel steering

A tiller at the back of the unit is used to steer the unit's two rear castors. The steering moves both rear castors together providing exceptional control and manoeuvrability. Operators are able to achieve a tight turning radius when the unit is being used in confined narrow areas.

We use only high-quality wheels and bearings in the assembly of our equipment. It is important that quality wheel components are used to make the rolling resistance as low as possible; a low rolling resistance makes the unit easy to move around.

Drum suitability

Drum suitability

Our pneumatic-powered ATEX / UKEX Universal Drum Rotator can handle a wide range of drum types and sizes used in industry, made from different material constructions. Drums that range between 50 and 220 litres can be handled within the adjustable band (350-610mm diameter). Additionally, drums of less than 350mm in diameter can be handled with a special attachment (INS01 option). For a detailed list of compatible drums please view our drum suitability document by clicking the button below.

ATEX / UKEX-certified unit for flammable / explosive areas

ATEX / UKEX-certified unit for flammable / explosive areas

ATEX and UKEX drum handling equipment is required in flammable environments, we have a long history of designing and building equipment for these hazardous environments. Having assisted hundreds of companies that handle drums in zoned areas we understand different applications and can offer ATEX and UKEX drum decanting equipment to suit.

Our manual-hydraulic and pneumatic-hydraulic drum rotators can be supplied 'Ex' rated, suitable for use in Zone 1, 2, 21 and 22 environments. Each of our drum decanting units is manufactured in the UK. Our engineers ensure electrical continuity throughout the unit and that a path to ground is always present for each model. Each piece of equipment is supplied with a manufacturer’s Declaration of Conformity which states compliance with the directives and relevant British and ISO Standards.

Specification

STP01-DRU01-SS-Ex Stainless Steel Drum Rotator (Pneumatic-ATEX / UKEX)

-

Safe working load (SWL)

350kg

-

Functions

Powered lift/lower, manual rotation, manual push/pull

-

Power details

Air powered - requires min: 400L/min, optimum: 760L/min at 6 bar with 13mm flexible air hose

-

Controls

Silicone booted buttons and emergency stop

-

Lift height

1400mm

-

Tipping clearance

1400mm at 15° tip angle / 1325mm at 30° tip angle (205 litre drum

-

Drum compatibility

Steel and plastic drums, 50-220 litres (incl. MAUSER drums)

-

Band assembly

Segmented adjustable/universal band with 50mm stainless steel ratchet and polyester strap

-

Additional drum securing

Rim clamp included which grips the top edge of the drum preventing slippage

-

Rotation gearbox

Worm-wheel, self-locking with 120:1 ratio and manual handle

-

Construction

Stainless steel 304-grade construction

-

Metal preparation

Aqua blasted and vibro-polished stainless-steel parts, smooth clean finish

-

Guarding

Anti-static polycarbonate shatterproof clear guarding

-

Leg dimensions

Inside straddle width 850mm, total outside width 1080mm

-

Front wheels

Two fixed 160mm wheels, aluminium centred with anti-static polyurethane tyres and precision bearings

-

Rear wheels

Two tiller steered 160mm wheels, aluminium centred with anti-static polyurethane tyres and precision bearings

-

Noise

Less than 76 dBA

-

Compliance

CE / UKCA

ATEX / UKEX (zones 1, 2, 21, 22)

Optional features

ATEX / UKEX option

We can offer an ATEX / UKEX version of this drum rotator model, suitable for use in zone 1, 2, 21 and 22 environments.Powered drum clamp

Increase output utilising hydraulic clamping arms. Using our unique flexible pads, operators can clamp drums from 50- to 220-litres.Powered drum rotation

For high-volume pouring applications we offer hydraulic power rotation. You can control drum tipping from either the rear panel or the front of the machine.Power-drive system

Our pneumatic power-drive system offers effortless control when moving drums over long distances.Telescopic/variable lift height

Single- and dual-mast models are available. Single mast units offer up to 1500mm of lift whereas telescopic units offer 2700mm.Variable leg dimensions

We can modify leg dimensions to suit your existing equipment and infrastructure.Fixed-size drum band

Our fixed over-centre drum band makes securing drums quick and easy. The fixed band is suitable for 200- to 220-litre steel and plastic drums.Load-cell weighing system

With our load-cell weighing system you can weigh drums while you handle them. A digital read-out provides real-time weight information ideal for batch production.Very small drum insert

We have designed an insert that allows you to lift small containers up to 50 litres in size.Sale or return

In the UK we can supply certain equipment on a sale-or-return basis, meaning you can use a unit on-site for seven days with no obligation to buy it once the trial period is up. Find out more here.

Technical specification

Contact Us

Do you have a manual handling issue we could solve? We’d be happy to discuss any handling concerns and advise on the most suitable STS equipment. You can talk to us via telephone, email and social media.

Drum Rotators / Tippers

Tipping drums is an essential part of many industrial processes. Our drum rotators provide a safe way to lift and tip various drum types and sizes, and we can customise each rotator to suit your exact needs.