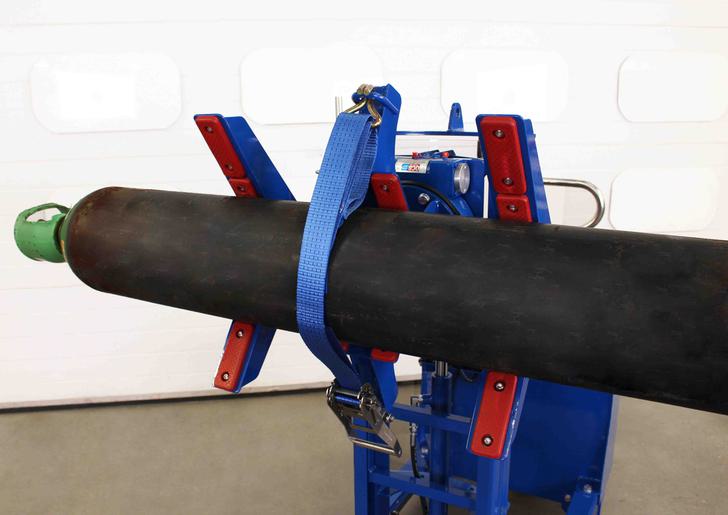

The unit has a rubber support pad to suit gas bottles with diameters between 180mm to 550mm, and heights from 1200mm to 1800mm. The operator secures the cylinder in place against the pad using a ratchet and strap mechanism before lifting and maneuvering it into position.

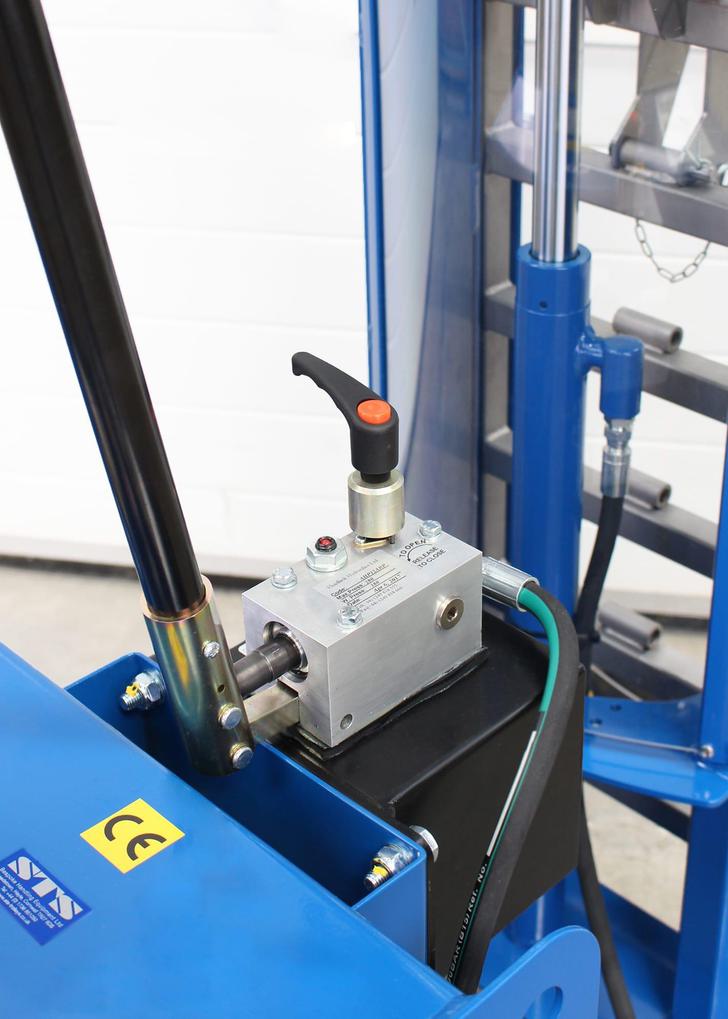

The rubber pads provide additional grip between the cylinder and support pad ensuring the load is held securely throughout the handling operation. To detach the cylinder the ratchet mechanism is released, this is done by pulling the ratchet lever and rotating the handle forwards.